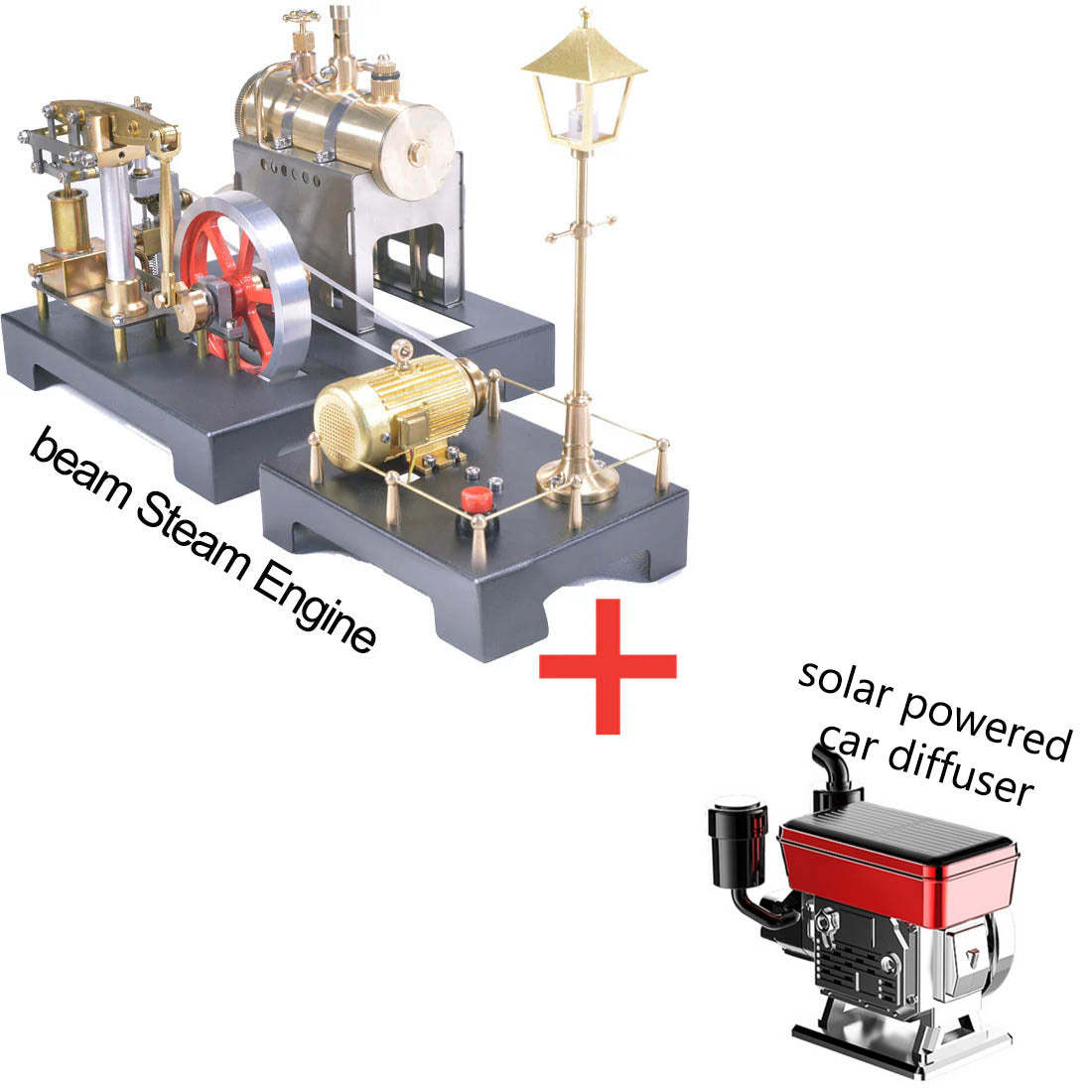

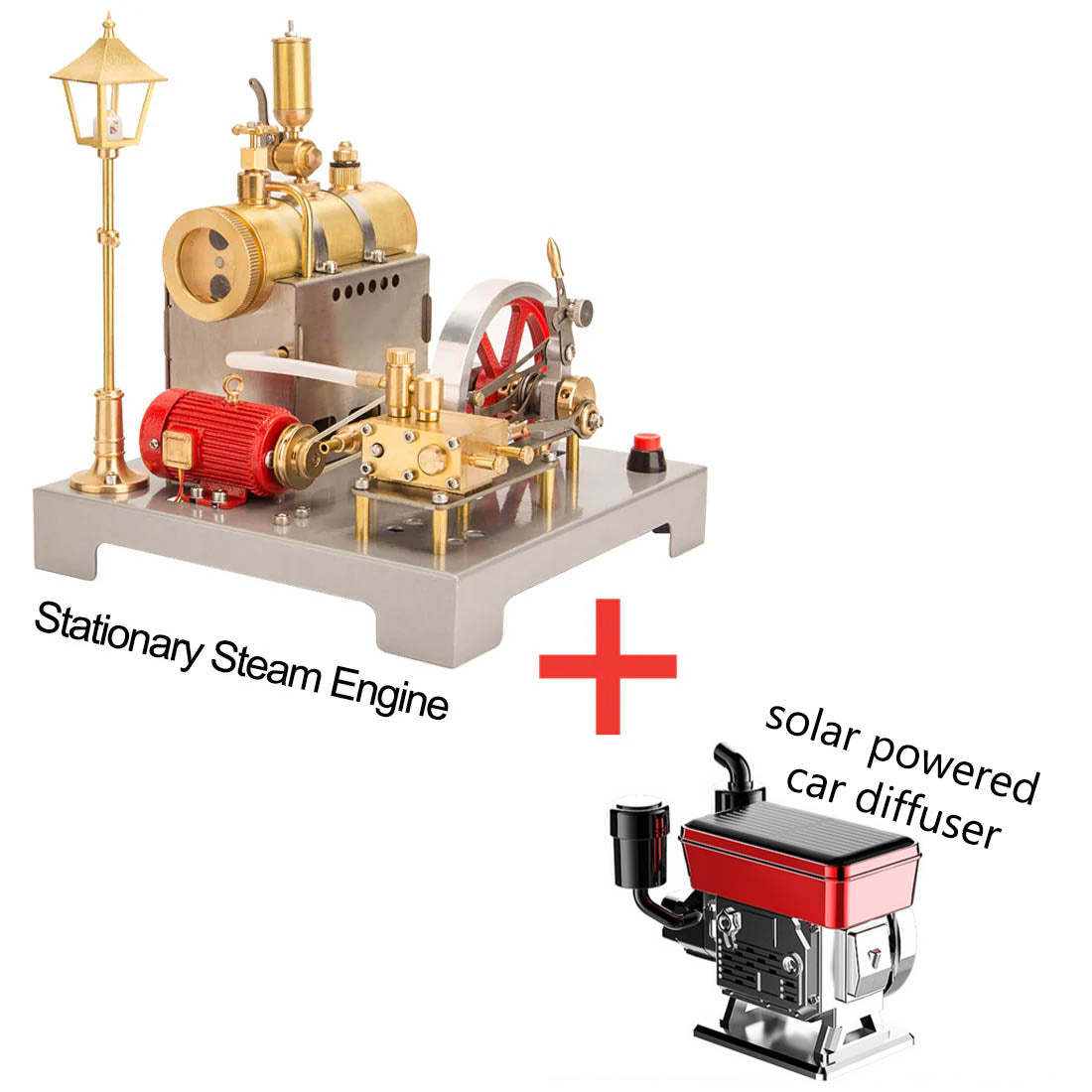

RETROL DIY Beam Steam Engine Model Kit with Boiler and Centrifugal Flyball Governor

Hero Section: The Heartbeat of the Industrial Revolution

Before electricity hummed in our walls, the rhythmic rocking of the Beam Engine drove the world’s industries. The RETROL DIY Beam Steam Engine is a tribute to that golden age of engineering. It captures the mesmerizing, slow-beat cadence of James Watt’s legendary design. This isn't just a model; it is a kinetic sculpture. Watching the beam rock gracefully while the flyball governor spins is a hypnotic experience that connects you directly to the mechanical soul of history.

Why Choose the RETROL Beam Engine?

- The Mesmerizing Flyball Governor: The standout feature of this model is the fully functional centrifugal flyball governor. As the engine speeds up, watch the brass balls spin outward, mechanically regulating the steam intake. It is a brilliant, visible demonstration of early automation and feedback loops.

- A Builder’s Journey: With 84 precision parts, this kit offers the perfect "Goldilocks" level of challenge—complex enough to be rewarding, but logical enough to complete in a few satisfying sessions. It transforms from a box of parts into a living machine under your hands.

- Heavy Metal Reality: Weighing in at nearly 2kg (1800g), this model commands respect. Made from high-grade metal, brass, and stainless steel, it sits solidly on your desk, free from the vibration and cheap feel of plastic alternatives.

- Living Education: There is no better way to understand thermodynamics and mechanical linkage than to build it. It turns abstract physics concepts into a tangible, hissing, moving reality.

Technical Highlights: Engineering Simplified

- Beam Action Mechanics: The engine utilizes a classic overhead beam design to convert the vertical motion of the piston into the rotational motion of the flywheel. This linkage reduces side-thrust on the piston, a hallmark of durability in early industrial engines.

- Centrifugal Regulation: The governor isn't just decoration. It mimics the physics of real steam engines where centrifugal force lifts the weights to close the throttle valve, preventing the engine from over-speeding.

- High-Torque Low RPM: Unlike high-speed racing engines, the beam engine is designed for torque and grace. Operating between 500-1000 RPM, it allows you to visually track every component's movement, making it a joy to watch.

- Integrated Boiler System: The kit includes a dedicated metal boiler with a safe, alcohol-based heating system, ensuring a self-contained power source without the need for external plumbing.

Specifications

- Material: Aluminum Alloy / Brass / Stainless Steel

- Part Count: 84 Pieces

- Dimensions: 18 x 18 x 17cm

- Net Weight: 1800g

- Speed Range: 500-1000 RPM

- Governor Type: Centrifugal Flyball

- Fuel: Liquid Alcohol (Recommended 95%)

- Assembly Time: Approx. 2-3 Hours

Usage Scenario: The Gentleman’s Study

It’s a rainy Sunday afternoon. You are in your study or garage, away from the glare of screens. You light the alcohol lamp and wait for the water to boil. A minute later, you give the flywheel a gentle nudge. The beam begins its rhythmic dance—up, down, up, down—accompanied by the soft hiss of steam and the clicking of the governor. It is the ultimate desk companion, providing a calming, mechanical focus that helps you unwind and think.

Important Tips from the Workshop

- Lubrication is Key: Steam is "dry," so lubrication is vital. Before every run, apply a drop of high-viscosity steam oil to the piston and the beam pivot points. This ensures the motion remains smooth and silent.

- Water Matters: Always use distilled water in the boiler. Tap water contains minerals that will eventually scale up and block the tiny steam ports, reducing performance over time.

- Governor Tuning: Ensure the linkage between the flyball governor and the valve is free-moving. If it's too tight, the governor won't spin freely; too loose, and it won't regulate speed effectively.

- Safety First: The boiler and steam lines get hot. Enjoy the visual spectacle, but keep fingers away from the hot zones during operation.

Customer Support

We are passionate about keeping history alive. If you encounter any issues during assembly or need advice on maintenance, our expert team is ready to assist. Contact us at service@helloworld7.com.