K006 Retro All-Metal Vertical Steam Engine Model with Solid Boiler 45min Runtime

Hero Section: A Tribute to the Industrial Age

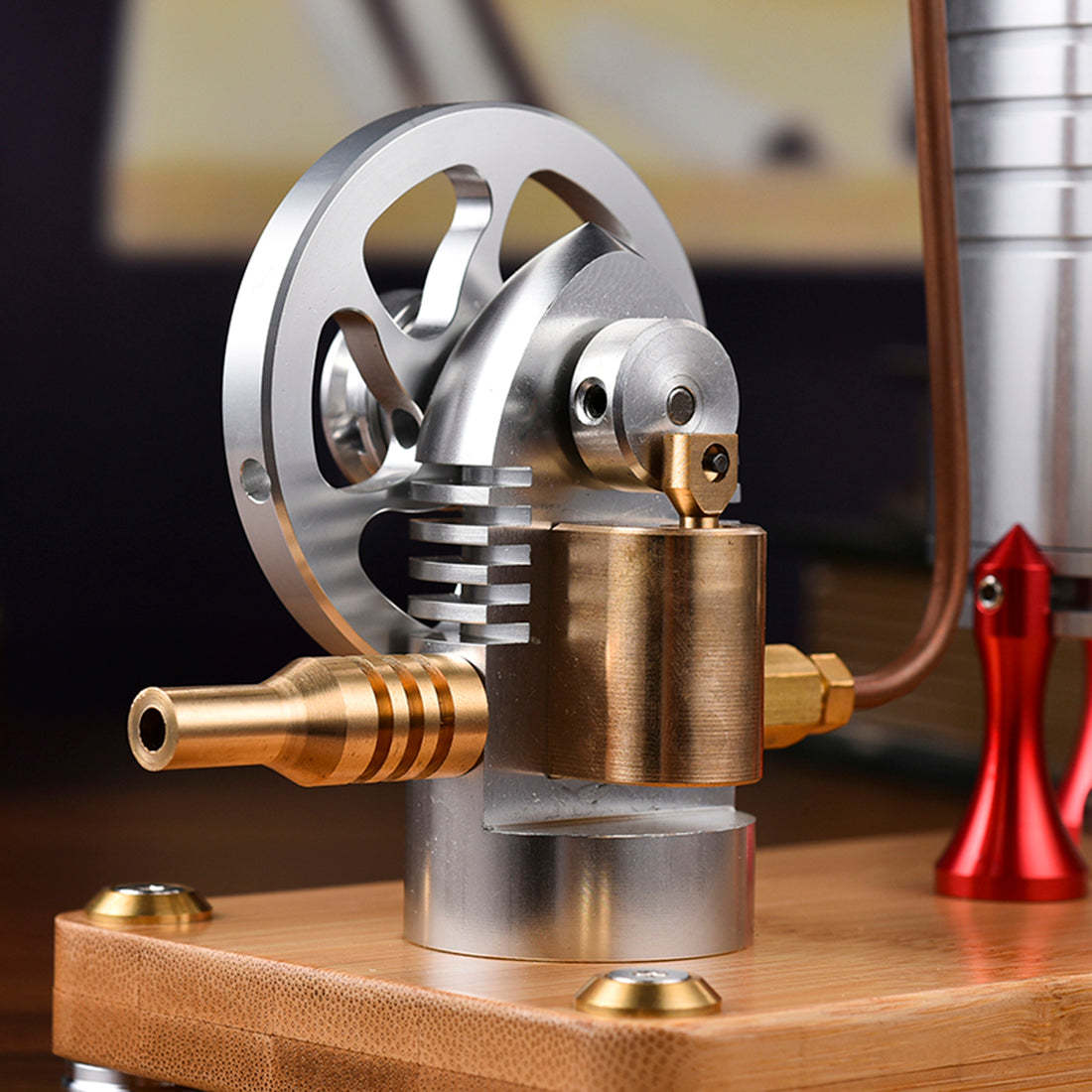

There is a mesmerizing quality to a vertical steam engine—the rhythmic rise and fall of the piston, the spinning flywheel, and the gentle hiss of steam. The K006 is not just a model; it is a kinetic sculpture that captures the spirit of the Industrial Revolution. Crafted from high-grade metal with a sophisticated frosted oxidation finish, this engine brings the heavy machinery of the past onto your desktop. Whether you are an educator demonstrating the power of thermal energy or a collector seeking a centerpiece that works as beautifully as it looks, the K006 delivers an unforgettable mechanical experience.

Why Choose the K006 Vertical Engine?

This model stands out for its robust construction and exceptional run time.

- Uncompromised Safety: The heart of this system—the boiler—is machined from a solid aluminum alloy rod, not welded sheet metal. With a single wall thickness of 3.5mm, it offers superior structural integrity and safety, giving you peace of mind during high-pressure operation.

- Extended Operation: Most mini steam engines run for 10-15 minutes. The K006, equipped with a high-capacity boiler and dual alcohol lamps, provides continuous steam power for approximately 45 minutes. Sit back and enjoy the show without constant refueling.

- Precision CNC Craftsmanship: Every component is processed via CNC cutting and grinding. The combination of aluminum alloy and brass ensures tight tolerances for smooth running, while the frosted color oxidation provides a permanent, premium finish that won't fade or rust.

- Complete Desktop Station: This is a turnkey solution. The engine, boiler, and fuel system are all mounted on a sturdy aluminum alloy base. It’s ready to display and run right out of the box.

Technical Highlights: The Expert’s View

- Double-Lamp Heating: To maintain consistent pressure for 45 minutes, the system uses two alcohol lamps. This distributed heat source ensures the water boils evenly and maintains the "sweet spot" of steam pressure required for the vertical engine.

- Integrated Safety Valve: The top of the boiler features a built-in safety valve. If pressure exceeds the operational limit, it automatically vents, preventing over-pressurization.

- Vertical Architecture: The vertical design minimizes friction and footprint, a layout historically used in marine and stationary factory engines for its efficiency and reliability.

Specifications

- Model: K006

- Type: Vertical Reciprocating Steam Engine

- Material: Aluminum Alloy & Brass

- Process: CNC Machining / Frosted Oxidation

- Boiler Construction: Solid Aluminum Rod (3.5mm Wall)

- Dimensions: 16cm (L) x 12cm (W) x 16cm (H)

- Weight: 1100g

- Runtime: Approx. 45 Minutes

- Heating Source: Dual Alcohol Lamps (Included)

- Package Weight: 1500g

Usage Scenario: The Evening Ritual

It’s a quiet evening in your study. You place the K006 on your desk. You unscrew the top valve, add water, and fill the twin lamps with alcohol. You strike a match. As the flames heat the solid boiler, you wait in anticipation. After a few minutes, steam begins to escape. You give the flywheel a gentle push, and the engine catches life. Chug-chug-chug. For the next 45 minutes, the rhythmic sound and motion provide a calming, mechanical backdrop to your reading or thinking. It’s analog therapy in a digital world.

Important Tips

- The 2/3 Rule: Never overfill the boiler or the lamps. Fill both water and alcohol to 2/3 capacity. This leaves necessary space for steam expansion and prevents fuel spills.

- Prevent Dry Burning: Never heat the boiler without water. Although the solid wall is thick, dry burning can damage the seals and internal finish.

- Heat Warning: The entire unit acts as a heat sink. Do not touch the boiler or engine parts during operation. Allow it to cool completely before refilling or storing.

Customer Support

We are dedicated to your mechanical hobby. If you have questions about maintenance or operation, please contact our technical support team at service@helloworld7.com